Fully Automatic Crushing Washing Recycling Machine/Plant/Equipment

Basic Info

| Model NO. | AWS-PP |

| After-sales Service | Local Service Available |

| Warranty | 2 Years |

| Material Processed | Post-Consumer/Post Industry/in-House Plastic Waste |

| Plastic Type | Post-Consumer/Post Industry/in-House Plastic Waste |

| Screw | None |

| Automation | Automation |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Name | Plastic Waste Washing Line |

| After-Sale Service | Free Spare Parts |

| OEM | Available |

| MOQ | 1PC |

| Supply Type | Customzied |

| Control | P.L.C Control |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Sample/Service Manual | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| Material | Iron |

| Transport Package | Wooden Pallet |

| Specification | CE, TUV, ISO |

| Trademark | ACERETECH |

| Origin | Zhangjiagang City, Jiangsu, China |

| HS Code | 8477209000 |

| Production Capacity | 100 Set/Year |

Packaging & Delivery

Package size per unit product 8000.00cm * 600.00cm * 500.00cm Gross weight per unit product 4500.000kgProduct Description

Fully Automatic Crushing Washing Recycling Machine/Plant/EquipmentProduct Description

With years of technology modification and process experience precipitation, ACERETECH has a variety of different solutions for recycling PP PE scraps (LDPE/LLDPE film, PP woven bags, PP non-woven, PE bags, milk bottles, cosmetic containers, vegetable and fruit boxes). With advanced modular design, ACERETECH can freely combine each standard module to provide to customers specialized solutions. ACERETECH team integrated the cleaning line technology in Europe and China and continuously optimized it. Finally, it developed a series of modular equipment that can adapt to the different characteristics materials. Aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling. It can realize a cleaning and recycling line and handle hard materials at the same time. And flexible plastic. Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular.Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.Our principal: best long-term production with lowest investment.

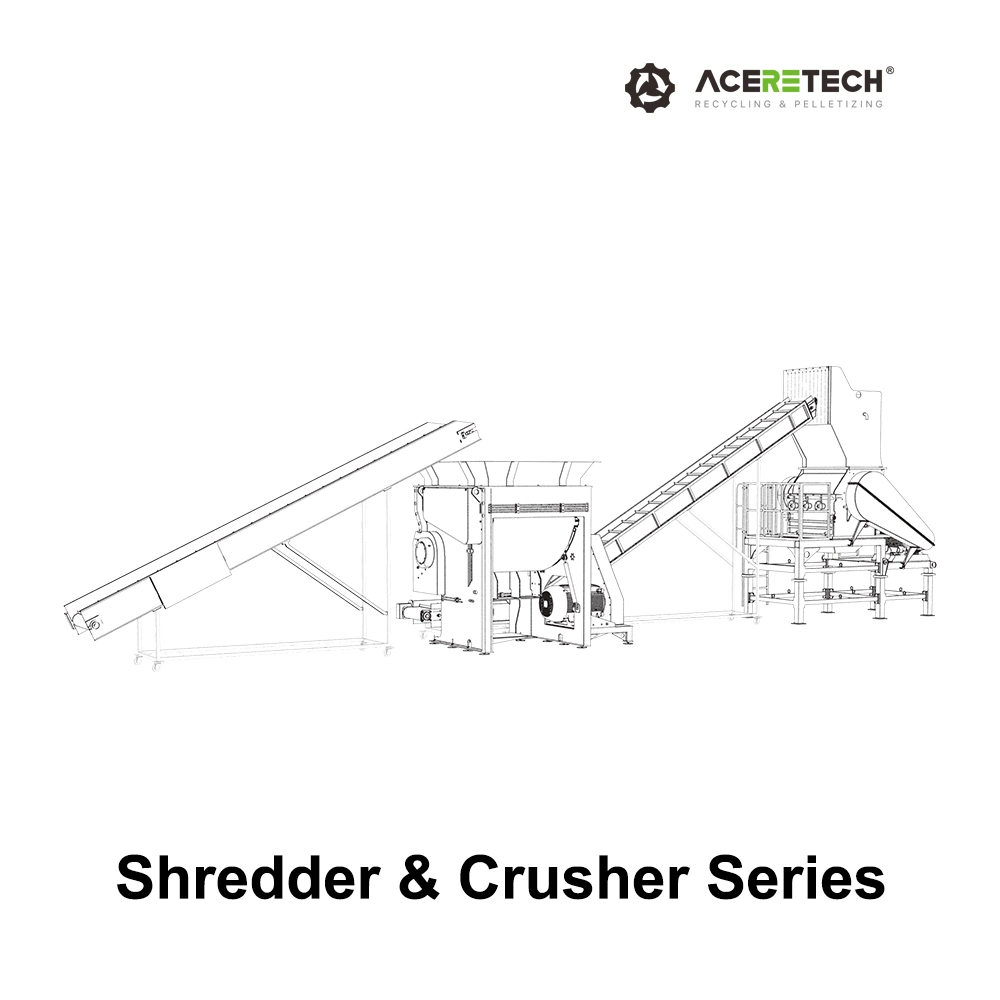

Main components of PP PE plastic washing line:

1.Input Belt conveyor

2.Shredder

3.L type belt conveyor

4.Magnetic separation belt

5.Pre-washer machine

6.Crusher

7.Screw loader

8.Friction washer

9.Flotating separation tank10.Friction washer11.Drying system( Squeezer, Centrifugal dryer, Pipeline dryer)12.Storage silo13.Electrical control cabinetProduct Parameters

Device parameters | |||

Size | Capacity | Motor Power | Equipment footprint |

AWS PP BAGS 05 | 500kg/h | 560KW | 150m 2 |

AWS PP BAGS 10 | 1000kg/h | 680KW | 300m 2 |

AWS PP BAGS 20 | 2000kg/h | 750KW | 450m 2 |

Unit energy consumption | |

Content | Average energy consumption per ton of bottle |

Electricity | 65-85KW |

Water | 4-6.5T |

Detergent (optional) | 2-4KG |

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME* ACERETECH is original manufacturer.* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.* Each component before assembly needs strict control by inspecting personnel.* Each assembly is in charge by a master who has working experience for more than 15 years* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factoryTHE AFTER-SALE SERVICE OF ACERETECH MACHINERY* After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.* After the commissioning, we will package the equipment by the standard export package for shipment.* According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.* Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.