Garlic Onion Ginger Powder Grading Sieving Vibration Straight Row Sieve Sifter Machine

Basic Info

| Model NO. | SZS-600 |

| Usage | Mine Shaker, Experiments Shaker, Lightweight Fine Shaker |

| Works | Dual Vibration Source Rotary Vibrating Screen |

| Object | Food Processing |

| Shaft Number | Other |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Other |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Support |

| Product Name | Dual Vibration Source Sieve Shaker |

| Material | Stainless Steel or Carbon Steel |

| Application | Powder/Granule |

| Capacity | by Model |

| Motor Type | Vibration Motor |

| Screen Size | 2~200mesh |

| Layer(S) | Single Layer |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Transport Package | Wooden Box |

| Specification | as per model |

| Trademark | Gaofu |

| Origin | Henan, China |

| Production Capacity | 10000set/Year |

Packaging & Delivery

Package size per unit product 110.00cm * 80.00cm * 70.00cm Gross weight per unit product 300.000kgProduct Description

Summary description

It is a new-type screening machine, using a single horizontal vibration motor, discharge the materials directly, having a greater handling capacity. It is used in screening granules and powders of flour, starch, detergent ,metal powder, additive, chemicals, non-mining industries etc. roughly, precisely. All products contact parts are made of stainless steel ,elegant design and durable, small dimension, save space and easy to move. Automated operations, a 24-hour continuous production.

1. The flat design of the inline sieve equipment is convenient for manual operation, small in size and easy to move

2. The inline screen can be connected in series to the production line system, with low energy consumption and high efficiency

3. The inside and outside are easy to clean, no hygienic dead ends, in line with the standards for use in the food and pharmaceutical industries

4. The automatic operation of the straight row sieve can be continuously produced for 24 hours

5. Ultra-quiet bass design, normally 70 decibels

6. The straight row sieve is tightly sealed, the liquid does not leak, and the dust does not fly

7. The unique structure and grid design of the straight-line sieve improve the durability of the screen, the screen can be changed quickly, and the disassembly and assembly are convenient, so that the problem of changing the screen can be completed within 5 minutes

Features

1.Inspection of raw materials and finished productsbefore package

2.Flat design,linear transmission of exciting force

3.Vibration source is convenient for maintenance

4.Match with magnetic separator to remove iron

Application range

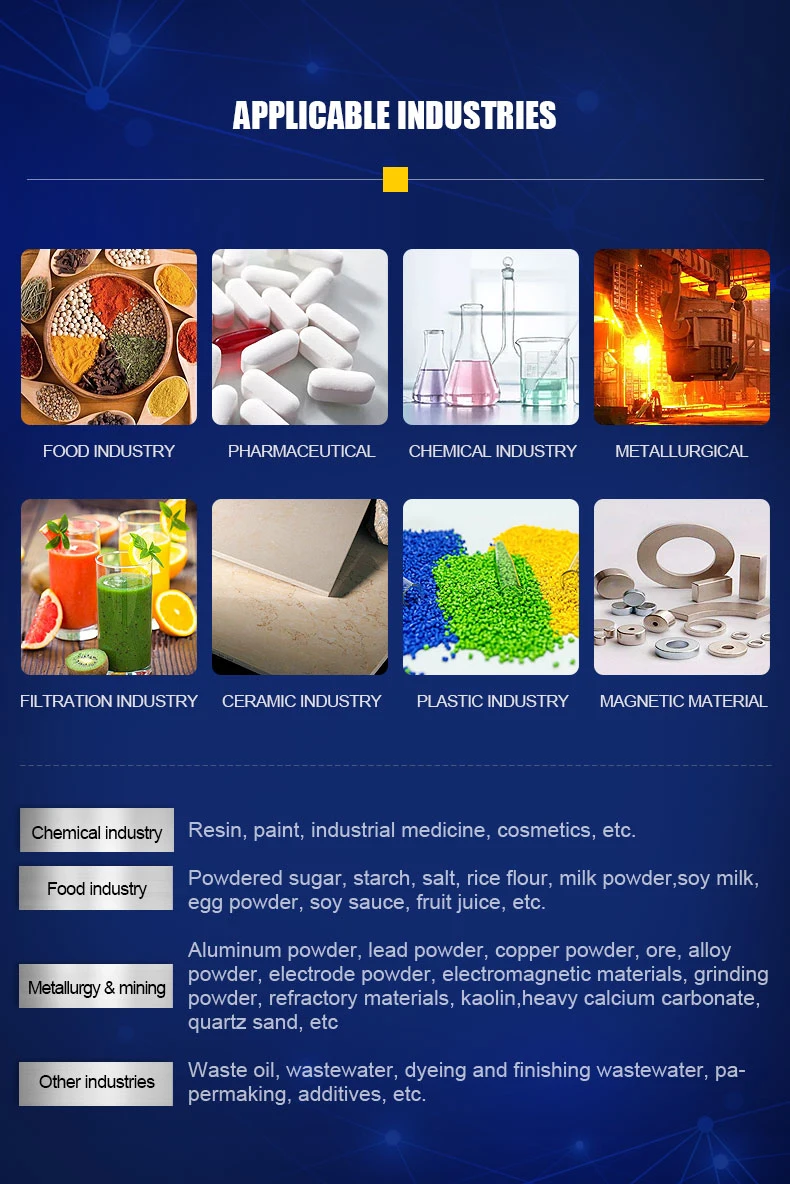

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Applied material

Flour, starch, milk powder, additives, carbon black (white carbon black), quartz powder (sand), mica, fluorescent powder, feldspar powder, kaolin, silica black soil, fly ash, glass beads, environmental protection, plastic, plastic, magnetic materials, building materials, mining, kiln industry, feed, seasoning, fish meal, rice flour, flour, soybean powder, milk powder, egg powder, starch, sugar, fruit juice, western medicine powder, traditional Chinese medicine powder, pharmaceutical intermediates, pearl powder, soda ash, poly Vinyl, resin powder (PVC, epoxy), washing powder, additives, paint, dye, pigment, rubber, paint, alloy powder, gold powder, silver powder, copper powder, aluminum powder, nickel powder, chrome powder, magnesium powder, zinc powder, barium powder, vanadium powder, titanium powder, strontium powder, lead powder, foundry sand, etc.

Product Parameters

Working principle

The straight row sieve uses a high-frequency vibration motor as the excitation source. After the material enters the system, it is subjected to the force of the vibration source to perform a three-dimensional rotational movement on the screen surface. warehouse. Impurities and foreign matter are separated and discharged to the slag discharge port, which acts as a "safety officer" on the production line.

| Model | Power(kW) | Motor Speed(r.p.m) | Sieve Diameter(mm) | Dimension(mm) | Weight(kg) |

| SZS-600 | 0.18 | 1450 | Φ580 | 1000×600×550 | 200 |

| SZS-800 | 0.25 | Φ780 | 1100×800×600 | 250 | |

| SZS-1000 | 0.55 | Φ960 | 1280×1000×700 | 330 | |

| SZS-1200 | 0.75 | Φ1160 | 1550×1200×750 | 400 | |

| SZS-1500 | 1.5 | Φ1460 | 1850×1500×900 | 750 |

Packaging & Shipping

Recommended Featured

Certifications

Company Profile

Xinxiang Gaofu Machinery specializes in manufacturing vibration screens and vibrating sieves. To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers. Thanks to production equipment, strong technical capabilities, improved detection means and strict managing system, we have enjoyed good reputation. our company has attained ISO9001:2000 certification and CE Certification. Our products sell well throughout China and are exported to North America, West Europe, Southeast Asia and other countries and regions. Do you want to improve your product quality? Do you want your products to become more competitive? Choosing Xinxiang Gaofu Machinery! We will be your friend in the way to success! And you will create a shiny future in 2017! Please visit our website: www.gaoful.com. Our tenet: "Honest Service, the Highest Quality".To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers.FAQ

1. who are we?We are based in Henan, China, start from 2000,sell to Southeast Asia(40.00%),Domestic Market(27.00%),South America(10.00%),Eastern Europe(8.00%),Oceania(3.00%),North America(2.00%),Western Europe(2.00%),Africa(2.00%),South Asia(1.00%),Eastern Asia(1.00%),Southern Europe(1.00%),Central America(1.00%),Northern Europe(1.00%),Mid East(1.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Contact Us

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

Your email addressand telephone will not be shared or published!The proper selection of the vibrating screen depends on the material, mesh size,output required, method of input,abrasiveness of the material etc: 1. Screening product : _____2. Moisture:_____%3. Capacity:________kg/ hour4. Screen layer:_______5. Screen mesh size:______ mesh . ______ mesh. ______ mesh6. Voltage:______V,Frequency:______HZ, 3 phase7. SS304/316L stainless steel or Q235A carbon steel?