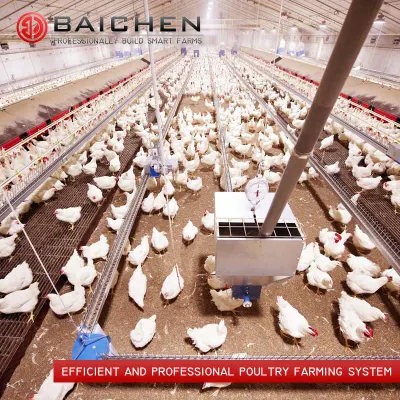

Breeder Chicken Chain Feeding Line Corner Wheel Poultry Feeding System

1. Main Feeding System (Silo) The feed is transported to the inside of the chicken coop via a main feed line conveyor sy

Basic Info

| Model NO. | BC-FL01s |

| After-sales Service | 1 Year |

| Type | Automatic Chicken Farm Feeding |

| Usage | Chicken Farm Automation |

| Application | Chicken |

| Power Source | Electric |

| Heating and Ventilation Equipment Type | Fan , Air Inlet , Cooling Pad |

| Epidemic Prevention Equipment | Mobile Vaccination Car |

| Blade Type | According to The User′s Situation |

| Computerized | Computerized |

| Certification | ISO9001:2008 |

| Condition | New |

| Warranty | 1 Year |

| Feed Pan Spacing | 3 or 4 Feeder Per 3m |

| Feed Pipe Material | Hot Galvanized |

| Feeder Material | PVC |

| Raising Quantity | 13-18 Chickens Per Squaremeter |

| Feature | Practical, Durable, Cheap |

| Life Span | More Than 15 Years |

| Transport Package | Container by Sea Way |

| Specification | Plastic. According to customer requirements |

| Trademark | Baichen |

| Origin | China |

| HS Code | 84362900 |

| Production Capacity | 50000PCS/Month |

Product Description

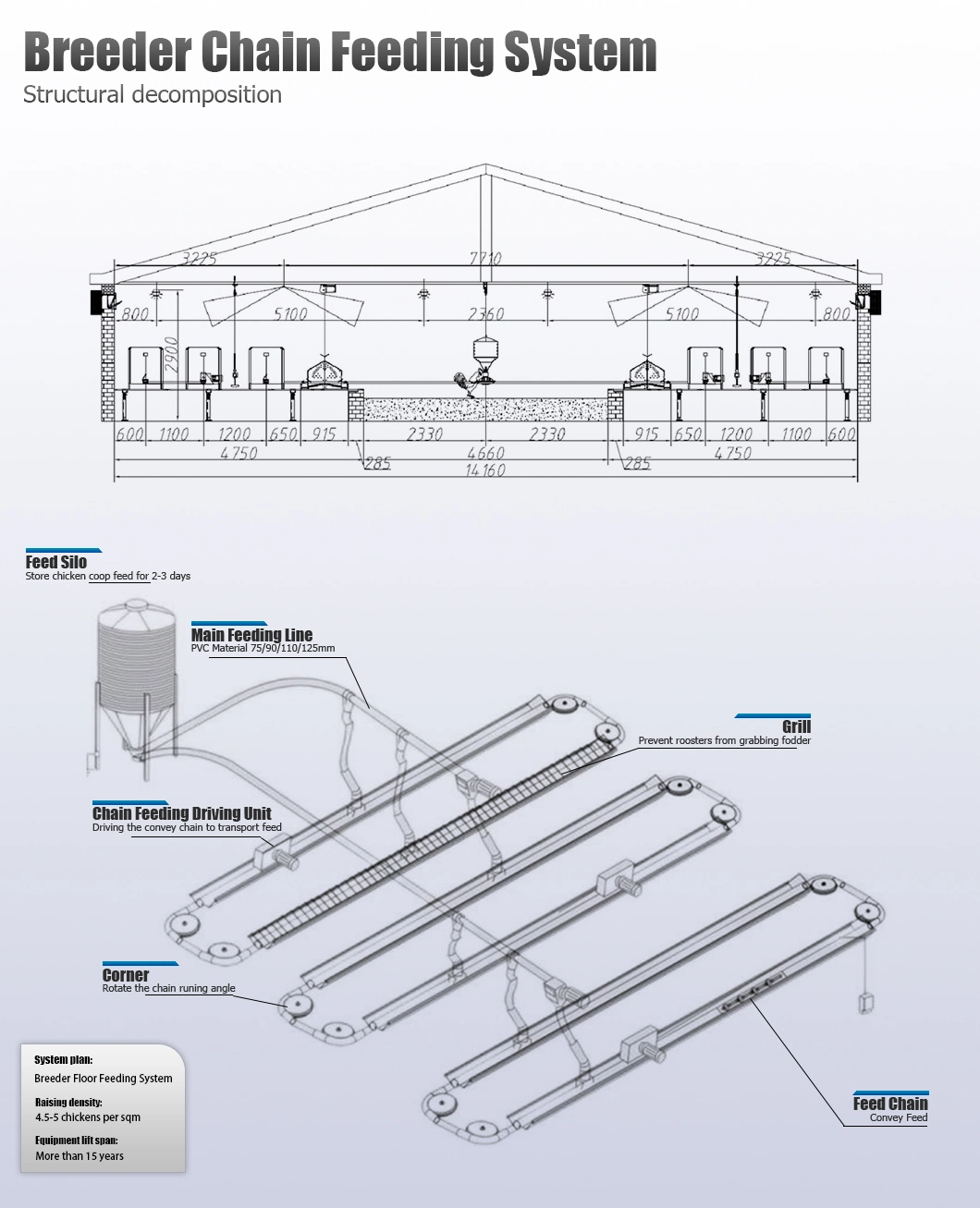

The feed is transported to the inside of the chicken coop via a main feed line conveyor system in the lower part of the storage tower, and the feed is transported separately to the individual distribution lines via hoppers. State-of-the-art storage systems ensure that feed is not easily contaminated and transport systems avoid loss of feed during transport

· Silo : 3Ton-34TonD

· Auger type feed uploading device for silo : Hot-dip galvanized material

· Drive Motor : motor(wanxin), 1.1KW 380V 50HZ 3-PHASE

· Feed sensor : IFM KI0209

· Main feed line : ∅75mm Auger (Technical System)

· Feed drop part : ∅75mm include soft pipe2. Chain Feeding Line System

After the hopper receives the dropped feed in the tee pipe, the feed is transported to the individual feed trays through the hot-dip galvanized pipe through the motor on the feed line, and the level sensor at the tail senses the amount of feed to avoid feed overflow

· Feeder : 4 feeders or 3 feeders /3 meters

· Driving Motor : motor(wanxin), 0.75 Kw 380V,50HZ,3-PHASE

· Feed Hopper : Hot-dip galvanized material

· Feed Tube : 4holes/3m/unit· Feed Sensor : IFM from Germany, time delay range 0 to 2 hours.· Hanging System : winch in the middle of house, hanging point 3m, all steel wire.· Anti-roost System 3. Nipple Drinking Line System

The chicken drinking water system in the chicken coop has been treated at the front end of the coop by a Dosatron brand filter/doser system, ensuring that the quality of the water does not make the flock sick

· Waterline Front System : Used to control the drinking system, including filter, water meter Dosatron medicator etc

· Pressure Regulator : 10-13KPA

· Main Water Inlet System : ∅32mm PVC

Connecting of Regulator and Re-flush Water Tube : include valve soft pipe

· Nipple Drinking System : 16nipples/4m/unit with drip cup

· Winch : 1500LB

· Hanging System : 3m distance

· Water-level Display Pipe

· Anti-roost System 4. Ventilation System of Fan and Air Inlet

The professional ventilation system is composed of an air intake window and a negative pressure fan, which can be connected to an advanced environmental control system to provide different ventilation times according to different chicken ages and solar terms, to ensure that the chickens will not die due to insufficient ventilation or temperature reduction

· Ventilation Fan : 50'' or 36" (1.1KW,380V,50HZ)

· Inlet : motor(wanxin), 0.75 Kw 380V,50HZ,3-PHASE5. Automatic Cooling Pad System

Cooling Pad can control the temperature and humidity inside the chicken coop, in the hot equatorial area wet curtain is essential, through the water pump to pour water on the cooling pad and cooperate with the negative pressure fan driven by the air flow, the internal humidity of the chicken coop is controlled within a suitable range, reduce the cluster mortality

· Cooling Pad : 16nipples/4m/unit with drip cup· Ventilation Fan : 50'' or 36" (1.1KW,380V,50HZ)· Winch : for pulling water line; for pulling deflector handle 6. Automatic Power Control and Environmenal System

The environmental control system is the core part of the automatic environmental control of the chicken coop, usually this system is based on experts and previous chicken raising experience to a certain degree of system preset, to ensure that less experienced farmers can also adjust the chicken coop environmental control system according to expert advice

· Environmental Controller: Baichen Controller Or Agrologic 607A

· Electrical Control System : output power 50kw,CHINA configuration

· Wires and Accessories : China standard wire7.Lighting system

The lighting system is a necessary system to promote the growth of chicken flocks. By simulating sunlight, the chicken flocks can obtain higher eating desire and vitality to ensure the growth of chicken flocks.

· LED bulb : LED 6W

· Wire : water proofing

| Poultry Breeder Floor Raising System Details | |

| Raising Quantity | 10000-30000 Chickens |

| Feed to meat Ratio | 1.8kg:1kg |

| Equipment Life | 15 Years |

| Manure Cleaning | Auto/Manual |

| Mortality In The Whole Raising Process | 3% |

| Initial Farming Cost | 1.3-1.5USD/Chicken |

| Epidemic Prevention Effect | Excellent |

Send to us