Zenbo Brand Fully Automatic Digital Sheet Feeding Assembling Brown Cement Craft Shopping Square Bottom Kraft Paper Bag Making Machine

Basic Info

| Model NO. | ZB1260SF-450 |

| After-sales Service | Yes |

| Warranty | 1 Year |

| Product Line | 1 |

| Lines | 1 |

| Voltage | 380V |

| Speed | 40-70bags/Min |

| Continuous-Rolled | No |

| Machine Type | Paper Bag Making |

| Computerized | Computerized |

| Glue Type | Water Soluble Cold Glue/Hot-Melt Glue |

| Paper Thickness | 120-190GSM |

| Handle Type 1 | Paper Twisted Handle |

| Handle Type 2 | Paper Flat Handle |

| Handle Pasting | Automatic |

| Hole Punching | Yes |

| Top Reinforced Card | Yes |

| Pre-Creasing Step | No |

| Transport Package | Vacuum Package & Wooden Box with Ippc Stamped |

| Specification | CE, ISO9001 |

| Trademark | ZENBO |

| Origin | China |

| HS Code | 8441200000 |

| Production Capacity | 10sets/Month |

Product Description

Fully Automatic High Speed Flat Handle and Paper Twisted Handle Switching Kraft Paper Shopping Gift Carry Handbag Bag Making Machine 1. Production DescriptionBrand new ZB1260SF-450 Fully automatic sheet feeding paper bag making machine (independent innovation) adopts international advanced production process and management system. Humanized intelligence operation interface combines with PLC and Servo control system make this machine's technology, performance and production efficiency achieve the leading level in the world.

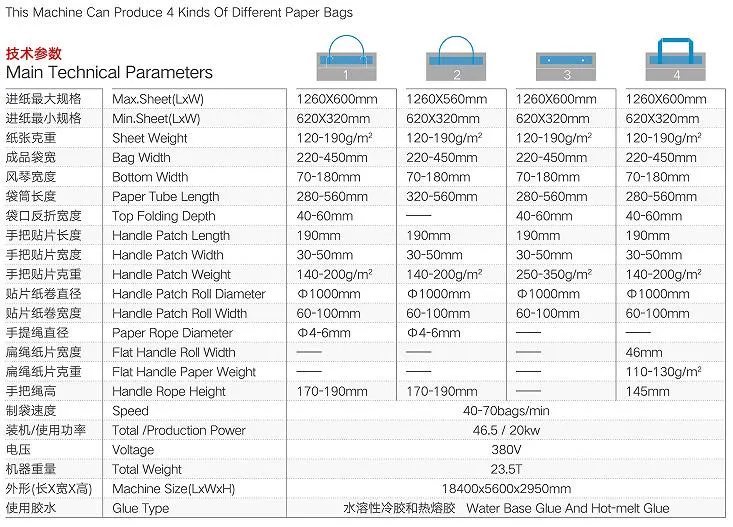

ZB1260SF-450 is a fantastic fully automatic paper bag making machine which can in-line produce both twisted rope handle and flat handle. This machine can produce 3 types paper bag, 3 different crafts as below:

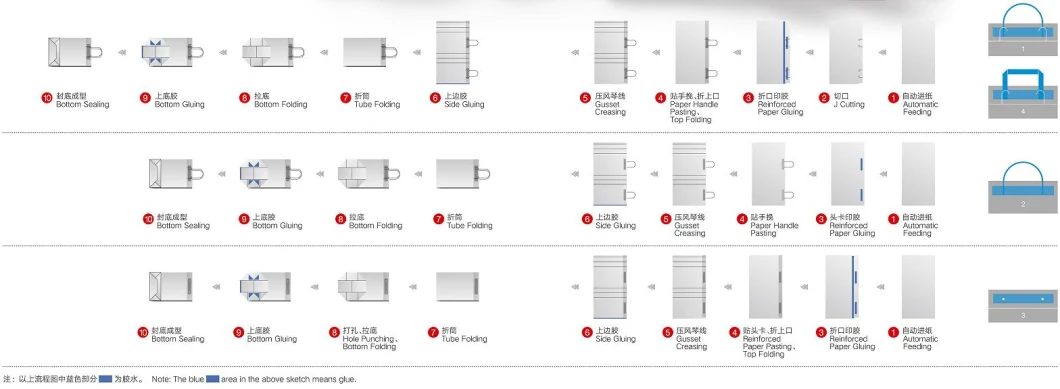

1.Paper handle making,handle pasting,top folding,tube forming,gusset forming, square bottom open,bottom gluing,bottom pasting,compaction output.

2.Paper handle making,handle pasting(without top folding),tube forming,gusset forming, square bottom open,bottom gluing,bottom pasting,compaction output.

3. Reinforce card making,reinforce card pasting,top folding,tube forming,gusset forming, hole punching,square bottom open,bottom gluing,bottom pasting,compaction output.

This machine equips advanced compact servo handle cut-off system to replace the traditional complex mechanical structure, which reduced the setup time and supplied a comfortable operation space. The bag making machine and handle making unit have separate servo control systems to avoid the handle waste. Intelligent switch between twisted rope handle and flat handle making supplies customers a wider range for various business.

- Feeder

- Front And Side Guides Positioning System

- Edge Cutting System

- Reinforced paper gluing system

- Handle pasting system (Flat handle and Twisted Round Handle)

- Servo reinforce paper cut off system

- Top folding system

- Automatic edge gluing system

- Automatic creasing and Punching system

- Thread rod to adjust bottom Clip system

- Bottom catch bag roller paper bag Fall down alert system

- Automatic collection system

2. Company Infromation

Zhejiang Zenbo Intelligent Machinery was established in 2009. We are professional for sheet feeding paperbag making machine. ZENBO machinery lead sheet-feeding paper bag making machine in China. We have worked with over 70% of high quality paper bag producer in China market and have 20 different types of paper bag making machine to meet the different kinds of demands for the customers. Besides, we have been exported to more than 40 countries for years.

3. Certifications

4. packing&shipping

5. Our Services

Service and technical support including the allocation of wearing parts, online fault know, installation and debugging, the purchaser`s worker training, software upgrade, The product specification, fault repair and other buyers concerned about the contents. For example:1.offers you the how to pre-sale service? Such as: whether or not to provide the sample? Sample charges? Where the party to bear the freight?Answer: can free to provide customers with bag samples were real machine proofing proofing, and shooting videofor customer reference.Send in the proofing paper provided by the customer, the paper freight provided by the customer, to complete the sample bag proofing can be sent free of charge by our company.2.you provide the service of how the sale? Such as: supplying method of wearing parts? Delivery cycle (orders started)?Answer: the damage in the warranty period of the fittings, our company in accordance with the warranty for its freereplacement. Product delivery cycle is generally for the signing of the contract within 45 days from the date of.3.after sale service? Such as shelf life? How to provide service within the warranty period?Answer: can provide 1 years of free warranty, long-term training services (the first free, second or subsequenttraining fees), the warranty period of machine parts can be damaged According to the number of free replacement parts.4.other special services? Such as the design, customization, installation, training and other services!Answer: other services include free training for the first time, subsequent paid training, and other technical support.MACHINE INSTALLATIONFor the purchase of new machines for customers, our company can arrange engineer to install machinery and for the training of machine operators; for the second time or more need to move Machine and training services, our company provides compensation for the movement and training services.