Sugar / Cassava Flour Rotary Sieving Grading Machine for Powdered Material

Basic Info

| Model NO. | YBS2000 |

| Shaft Number | Single |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Rubber Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Material | SUS304 or Carbon Steel Q235 |

| Layers | 1-5 Layers |

| Particle Size | 0.074-20 mm |

| Motor | Yzul Vibration Motors |

| Power | 3 Kw |

| Transport Package | Wooden Case |

| Specification | YBS1200, YBS1600, YBS2000, YBS2200 |

| Trademark | SYT |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 1000-4000 Kg/H |

Product Description

Sugar / Cassava Flour Rotary Sieving Grading Machine for Powdered Material Sanyuantang powder tumbler sieve grading machine is an efficient sieving equipment which is designed to meet the large out put, high-density sieving of the manufacturers. It is the most effective simulation of artificial sieving movement (sieving precision, efficiency,service life is 5-10 times than the common cylinder sieve), for the processing of all the fine and ultra-fine powder and special materials, particularly suitable for materials which are difficult to classify.Working Principle of Silicon powder tumbler screen

Because of the motion trajectory of the griddle box, the Tumbler screen machine is also called compound circle screen. The vibration force produced by the drive system is a kind of inertia force which is circling the dead axle and changing regularly. Intrinsically, it is a kind of centrifugal force given by the eccentricity mass circling around the dead axle. The sieve is ususlly installed horizontally or with tiny angle(0°-5°).

Technical Data of powder tumbler vibrating screen sifter

Model | Availability of screening area (m*m) | Screen slope (angel) | Grain size(mm) | Frequency(r/min) | Double amplitude(mm) | Power(kw) | Process capacity(t/h) |

HXSY-600 | 0.292 | 0-10 | ≤100 | 750 960 1500 | 5-8 | 0.25 | 6-10 |

HXSY -1000 | 0.785 | 5-8 | 1.5 | 8-15 | |||

HXSY -1200 | 1.13 | 5-8 | 2.2 | 15-30 | |||

HXSY -1600 | 1.83 | 5-8 | 2.2 | 25-50 | |||

HXSY -2000 | 2.63 | 5-8 | 4.0 | 30-60 | |||

HXSY -2600 | 5.31 | 5-8 | 5.5 | 45-60 |

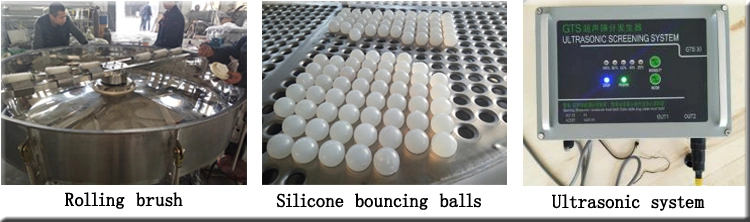

Photos of tumbler vibrating screen sifter machine

Applications of powder tumbler vibrating screen

Tumbler Screening Separator is suitable for food industry, pharmaceutical industry, chemical industry and other spherical, cylindrical, flake, or even irregularly shaped materials that are easy to block the net and require precise screening. Application materials: citric acid, milk powder, starch, sugar, vitamins, spices, tea, feed, plastics, rubber, fertilizer, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin, etc.

Xinxiang Sanyuantang Machine is located in Xinxiang High-tech Industrial Zone. It is a large-scale vibration equipment enterprise integrating scientific research, production and sales. In 2016, it passed the ISO9001 international quality management system certification. The company is committed to the production and sales of vibrating screen equipment, conveying and lifting equipment. Our products mainly include gyratory sieve , circular tumbler screen, rotary vibrating screen, ultrasonic vibrating screen, linear vibrating screen, filter sieve, air flow sieve, ,lab test sieve shaker, and a series of products such as conveying and lifting equipment.

FAQQ:What factors I need to get a quotation? 1> Material name: _____, bulk density :_____kg/m³ or ____g/cm³,and water content about _____%.2> Capacity required___kg/h3> How many layers?____ layers.4>The mesh size for each layer: ____ mm, ____ mm, ____mm. Or ____ mesh, ____ mesh, ____ mesh.5> Voltage and frequency:____V, ___HZ, 3 phase6> Sea port name or address for shipment.

Q:What is the real delivery time of your factory?

A: 10 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipment are the most durable type in the industry, this is also the feature of the label impression of SYT for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include. If you are interested in our products, please feel free to send me an inquiry or contact any time. I will provide you with the best service and the most favorable price.

Please write down your inquirement, and send to me!