LPG-100 Series High Speed Centrifugal Special Energy-Saving Drying Machine Spray Dryer for Vulcanized Colloid

Basic Info

| Model NO. | LPG-100 |

| Heat Source | Electricity, Steam, Coal Gas, Natural Gas, Fuel |

| Type | Centrifugal Spray |

| Name | LPG Series Centrifugal Spray Drier |

| Spay Type | High Speed Centrifugal Atomizer |

| Materials of Machine | Stainless Steel |

| Certificate | CE |

| Max Evaporated Zmount of Moisture(Kg/H) | 100 |

| Revolution of Atomizer(Rpm) | 18000 |

| Diameter of Tower(mm) | 150 |

| Diameter of Tower(M) | 2.7 |

| Power of Electric Heating(Kw) | Vapour Steam+36 |

| Overall Dimension(L×wxh) | 5.2×3.5×6.7 |

| Transport Package | Seaworth |

| Specification | Customizable |

| Trademark | stdrying |

| Origin | Jiangsu Changzhou |

| HS Code | 8419399090 |

| Production Capacity | 5 Sets/Month |

Product Description

Description

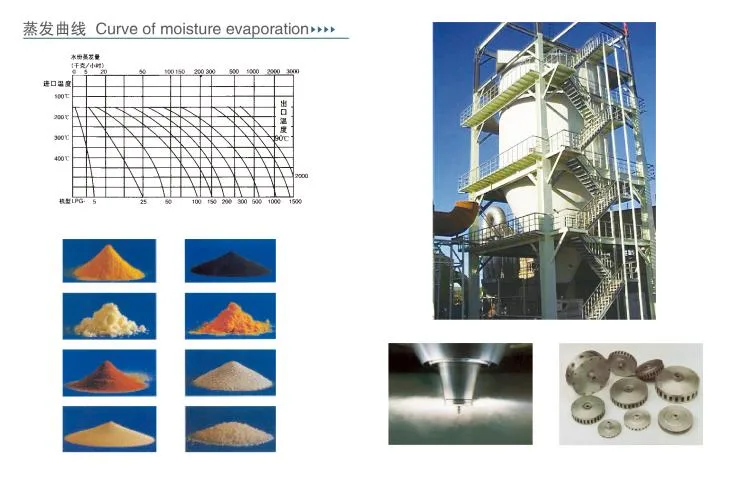

LPG series high-speed centrifugal spray dryer is a special equipment and suitable for drying emulsion, suspending liquid,liquor and so on. particularly it is good for drying polymers and resins; dyestuff and pigment; ceramics, glass; derust agent; pesticide; carbohydrate, dariryproducts; detergent and surfactant; fertilizer, organic compound, inorganic compound and so on.

Principle of work

Air pass through air filter and heater, enters into hot air distributor at the top of dry chamber. then enters into dry chamber vuiformly with helix. At the same time liquid of raw material is sent to centrifugal atomizer at the top of dry chamber by pump through filter, liquid of raw material atomizers small drops Air and liquid of raw material flow and contact fully, The moisture vaporize rqpidly, and raw material is dried into powderstate in a short time. The finished product is discharged through cyclone seperator from the bottom of dryer tower, The exhausted air is dischanged through fan.

Features

1.Its dry speed is very quick. Usually, it needs 5-15 seconds.It has feature of momentary dry.2. Because raw material can be dried momentarily. Especially, it is suiable for drying heat sensitive raw materials. It can maintain color, flavor and smell of raw materials.3.Its operation is stable and simple. Its regulation and control is very convenient It is easy to realize continuous production.4.The distribution, fluidity and solubility of product are good.

Product Parameters

| typeitem | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG-200 | LPG-500 | LPG-1000 |

| max evaporated zmount of moisture(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800-10000 |

| spay type | high speed centrifugal atomizer | |||||||

| revolution of atomizer(rpm) | 25000 | 18000 | 16000 | 11000-13000 | ||||

| diameter of tower(mm) | 50 | 120 | 150 | by craft | ||||

diameter of tower(m) | 0.9 | 1.75 | 2.3 | 2.7 | 3 | 3.2 | 4.7 | 5-14 |

power of eletric heating(kw) | 9 | 31.5 | vapoursteam+18 | vapoursteam+36 | vapoursteam+54 | by craftby craft | ||

| heating source | electric,stream+el | ectric and oil fuel,gas fuel,hot air furnace | ||||||

overall dimension(L×WxH) | 1.6x9.1*1.75 | 4x2.7x4.5 | 4.5×2.8×5.5 | 5.2×3.5×6.7 | 7×5.587.2 | 7.5x6*8 | 12.5x8x10 | Design layout according to plant site conditions |

Enterprise Spirit: Management, the soul; people, the foundation;Enterprise culture: Diligence rewarded by God, honesty rewarded in business. and perfection rewarded in professionalism;Enterprise policy: Good quality for surviving and development;Enterprise Characteristic: people-oriented in guidance; common efforts in action.Jiangsu Shuntong Drying Technology is located in Changzhou City, Jiangsu Province, a famous industrial city. It is a professional enterprise specializing in equipment design, manufacturing, sales and industrial heat energy research. It is currently a professional and systematic enterprise in the production of drying equipment in China. China's drying technology industry enjoys a high reputation.The company has complete production equipment, including 50 sets of various processing equipment. In order to improve product quality, the company uses CNC flame cutting machines, and has industry-specific equipment such as folding machines, shearing machines, plate rolling machines, and resistance welding machines. The metal cutting machine tool in the metal processing workshop is fully equipped with planing, milling, drilling and so on. The company's equipment operators are skilled workers with rich experience. The company has sufficient raw materials, complete hardware warehouse accessories, and the annual production capacity of various drying equipment exceeds hundreds of sets.The company pays attention to technology research and development, and the technical directors are experienced senior engineers with 20 years of experience in drying equipment design and production. The company has a number of patents. (Closed circulation boiling drying unit, closed circulation spray drying unit, waste heat recovery heat exchanger, low temperature belt drying unit) The company adopts the advanced management concept of combining China's national conditions and the actual development of the enterprise, and constantly attracts high-quality, high-level employees. The joining of management and technical talents has rapidly improved the competitiveness of the company, established an ISO9001 international quality certification system, and a complete set of advanced product research and development, processing and testing equipment, and cultivated a group of dedicated and strong service teams. Years of hard work, the company has accumulated a wealth of pharmaceutical, chemical, food and other drying equipment design, manufacturing experience, the products are widely used in various industries.The company always adheres to the business philosophy of people-oriented and honesty first, attaches great importance to the introduction and cultivation of talents, pays close attention to technological innovation, strictly grasps quality management and continuously strengthens the professional construction of enterprises to stand out in the fierce market competition.We adhere to the style of following people's hearts and working together to act together. We sincerely welcome friends from all walks of life to visit us for guidance, professional exchanges, and technology seminars. We will provide you with the best quality products and thoughtful services. Let us work together to create brilliant!

PACKAGE:Standard export carton packing.DELIVERY TIME:3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Q Are you trading company or manufacturer?A We are factory. Q How long is your delivery time?A Generally within 30-60 working days after receiving the payment. Q Do you provide samples? is it free or extra?A Yes, we could offer the sample .Considering the high value of our products ,the samples is not free , but we can give you best price including the freight cost.Q What is your terms of payment?A 95% payment before shipment or according to the terms agreed with the customer, the remaining 5% as the quality guarantee deposit, one year later.