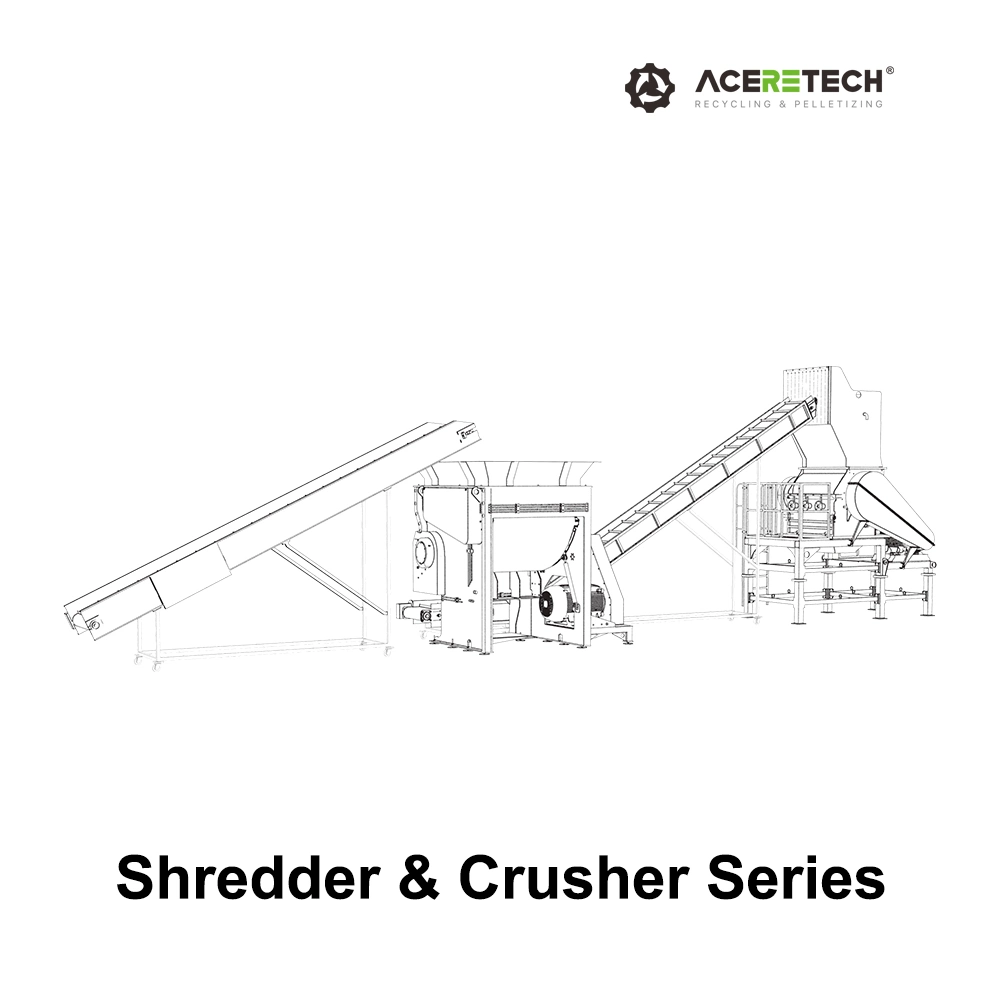

High Stability Aluminum Foil Film Plastic Crushing Recycling Equipment

Overview Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kg High Stab

Basic Info

| Model NO. | GH(024) |

| Raw Material | Post-Consumer/Post Industry/in-House Plastic Waste |

| Structure | Tangential Feed |

| Knife Classification | Piece Knife Crusher |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, CE SGS BV ISO |

| Condition | New |

| MOQ | 1 Set |

| Key Selling Points | High Productivity |

| Production Capacity (Kg/H) | 200-6000kg/H |

| Suit for | Automobile Recycling |

| Applicable Industries | Manufacturing Plant |

| Shaft Design | Single |

| Use | Waste Plastic Crusher |

| After-Sale Service | Free Spare Parts |

| OEM | Available |

| Supply Type | Customzied |

| Control | P.L.C Control(Imported Brand) |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Sample/Service Manual | Available |

| Transport Package | Wooden Pallet |

| Specification | CE, TUV, ISO |

| Trademark | Aceretech |

| Origin | Jiangsu, China |

| HS Code | 8477800000 |

| Production Capacity | 10 Set/Sets Per Month |

Packaging & Delivery

Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kgProduct Description

High Stability Aluminum Foil Film Plastic Crushing Recycling Equipment

Product DescriptionGH heavy-duty crushers are designed for size reduction of tough materials and to meet high grinding requirements with overall steel welded structure. GH crushers have a solid crushing cavity and are equipped with a variety of rotors. Rotor diameter cover from 700mm to 1100m, while rotor length ranges from 700mm to 2400mm. GH crusher has large rotor bearings and "V" shaped rotor,which improves cutting efficiency and reduces dust in the flakes. By adding a dismountable deflection wedge (the third fixed knife), GH crusher is able to granulate more various materials and quickly increase production. Anti-wear plates in the crushing cavity and external bearings help to reduce the risk of contaminants entering the crushing chamber.Application:GH heavy-duty crushers are widely used in size reduction of profiles, pipes, film, sheets, large rigid lumps.,etc.Product Parameters

| Item | Unit | GH700/700 | GH700/1000 | GH700/1200 | GH800/1400 | GH800/1600 | GH800/2000 | GH1100/1200 | GH1100/2400 |

| Rotor diameter | mm | 700 | 700 | 700 | 800 | 800 | 800 | 1100 | 1100 |

| Rotor width | mm | 700 | 1000 | 1200 | 1400 | 1600 | 2000 | 1200 | 2400 |

| Number of rotor knives | pcs | 7*2/5*2 | 7*2/9*2 | 7*2/9*2 | 3*2/5*2 | 7*4/9*4 | 7*4/9*4 | 7*2/9*2/11*2 | 7*2/9*2/11*2 |

| Number of stator knives | row | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2*55/2*75 | 2*55/2*75 |

| Chamber size | mm | 690*690 | 985*800 | 1150*815 | 1360*910 | 1570*915 | 1960*915 | 144 | 144 |

| Motor power | kw | 55 | 90 | 110 | 132 | 160 | 160*2 | 200 | 200*2 |

| Machine length | mm | 2250 | 2815 | 2815 | 3100 | 3100 | 2755 | 3115 | 3060 |

| Machine width | mm | 1900 | 2060 | 2360 | 2660 | 2860 | 4655 | 2440 | 3830 |

| Machine height | mm | 2950 | 3420 | 3770 | 3820 | 4085 | 4775 | 4430 | 4430 |

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

Send to us