What Equipment Does The Sand and Gravel Production Line Have

Overview What equipment does the sand and gravel production line haveThe sand and gravel production line is not only a f

Basic Info

| Running Track | Linear Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Online Video Guidance |

| Transport Package | Standard Export Plywood Case |

| Specification | Customizable |

| Trademark | TFZD |

| Origin | Xinxaing, Henan |

| HS Code | 8474100000 |

| Production Capacity | 2000pieces/Years |

Product Description

What equipment does the sand and gravel production line haveThe sand and gravel production line is not only a fine sand reclaimer but also one of the equipment that belongs to the intermediate link of the production line. For those who do not know the sand and gravel production line very well, what equipment is required for the sand and gravel production line to produce, coarse sand, fine sand, medium sand, and various stones? Today, Tianfeng Vibration will tell you the most basic, equipment required for the sand and gravel production line, Or what the sand and gravel production line is composed of that equipment.A complete set of sand and gravel production line, quartz sand production lines, construction sand production line,s, and stone production lines are composed of a vibrating feeder, jaw crusher, sand-making machine, sand washing machine, vibrating screen, and belt conveyor. The generation process is rough as follows: silo ->vibrating feeder ->jaw crusher ->impact crusher (optional) ->impact crusher ->vibrating screen ->sand washer ->fine sand recovery machine (finished sand). The equipment is connected by a chute or belt conveyor in the middle.

Due to the reasonable matching of crushing equipment at all levels and the strict spatial cross layout, it has the characteristics of a small floor area, high degree of automation, low operation cost, high investment, and economic benefits, good quality of the crushed stone, and low yield of stone powder. The produced machine-made sand conforms to the national construction sand standard, with uniform grain size, good grain shape, and reasonable grading.

The production line can flexibly adjust the size of the finished sand and stone according to the different particle size requirements of the sand and stone aggregate in different construction periods and can produce marketable products in time. It can be used for multiple purposes in the first line, greatly reducing the project investment.

In addition to the startup, shutdown, and routine maintenance of the equipment, the sand and gravel production line hardly requires manual operation. It has high production efficiency, low operation cost, large output, high profit, uniform grain size, and good grain shape of the finished stone, which meets the national requirements for high-speed material use.

Due to the increasing demand of various infrastructure and engineering buildings for sand and gravel aggregate, the application of sand and gravel production lines is becoming more and more common. Which machines are required for configuring the sand and stone production line? It is necessary to combine the processing requirements of users. Tianfeng Vibration provides you with a detailed configuration list for reference!

Henan Tianfeng Vibratory Machinery and Equipment is a domestic manufacturer specializing in the production of fine sand recovery machines, sand washing machines, dehydration screens, and sand washing and recovery machines. Users from all over the country are welcome to visit our company for on-site inspection and purchase.

Technical parameters of linear vibrating screen

Guidance on the use and maintenance of linear vibrating screen

1. The machine shall be equipped with electrical protection device.

2. At the initial operation stage of the machine, the anchor bolts shall be checked at least once a day to prevent looseness.

3. When the motor rotation direction does not meet the requirements, adjust the power supply phase sequence.

4. The motor shall be well lubricated, and lithium base grease (ZL-3) shall be added once every two weeks of operation. When refueling, an appropriate amount of lithium base grease shall be added through the oil cup. When sealed bearings are used, the motor is not equipped with oil cups.

5. After the machine has been running for 1500 hours, check the bearing and replace it immediately in case of serious damage.

6. When the machine is used again after being stopped for a long time, the insulation resistance should be measured, which should be greater than 0.5 megohms for a 500-volt megger measurement.

Daily maintenance of linear vibrating screen

1. Before starting:

(1) Check whether the coarse mesh and fine mesh are damaged;

(2) Check whether the transportation support is removed.

2. At startup:

(1) Pay attention to whether there is abnormal noise;

(2) Whether the current is stable;

(3) Whether the vibration is abnormal.

3. After use: clean up after each use.

Regular maintenance of linear vibrating screen

Regularly check the coarse screen, fine screen, and spring for fatigue and damage, and check whether all parts of the machine body are damaged due to vibration. The parts that need to be lubricated must be lubricated.

Applicable industries

Chemical industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, urine, waste oil, food wastewater, wastewater processing, etc. Processing process Production workshopThis is our inner workhouse.

some small equipment or parts will be made from here.

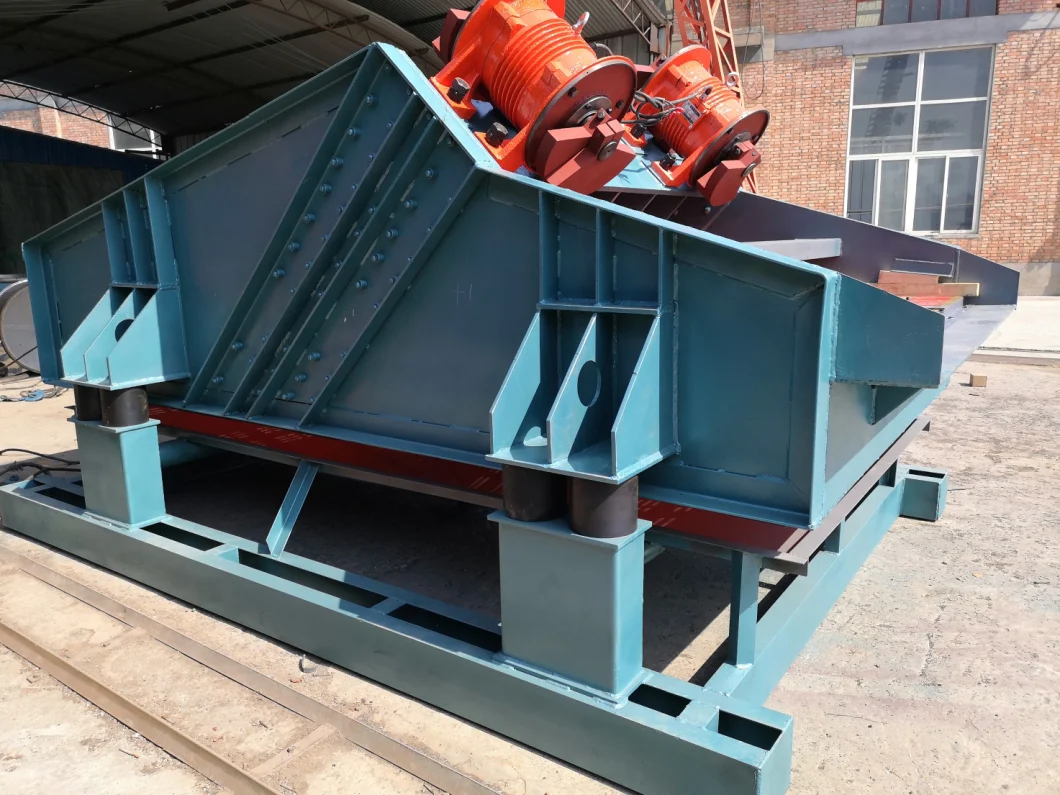

There are cranes, laser cutting machines, electric welding machines, platen machines, angle grinders, polishing machines, forklifts, and other equipment. Here is our outdoor operation platform.

We often produce and assemble large machines here.

There are electric welding machines, polishing machines, large cranes, and forklifts. Packaging & ShippingAfter you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.Customer visit

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

Send to us