Particle Coffee Grading Sieving Circular Vibratory Separator Screen

Basic Info

| Model NO. | From 400mm to 2000mm |

| Type | Circular |

| Function | High Frequency Vibrating Screen |

| Transmission Structure | Vibrating Screen |

| Usage | Mine Shaker, Experiments Shaker, Lightweight Fine Shaker, Screening Machine |

| Works | Vibration Motor |

| Object | Food Processing |

| Shaft Number | Single |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Stainless Steel Springs |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Product Name | Vibratory Separator Screen |

| Layer | Upto 5 Layer |

| Diameter | From 400mm to 2000mm |

| Type of Screen Frame | L-Shape |

| Design | Compact Design, Dust Proof |

| Material of Screen | Stainless Steel 304 |

| Quality | Superior |

| Screen Accuracy | More Than 95% |

| Motor Protective Grade | IP55 or IP65 |

| MOQ | 1 Set |

| Transport Package | Wooden Case |

| Specification | size depends on capacity you asked |

| Trademark | Hengyu |

| Origin | Xinxiang, China |

| HS Code | 84741000 |

| Production Capacity | 250 Sets Per Month |

Product Description

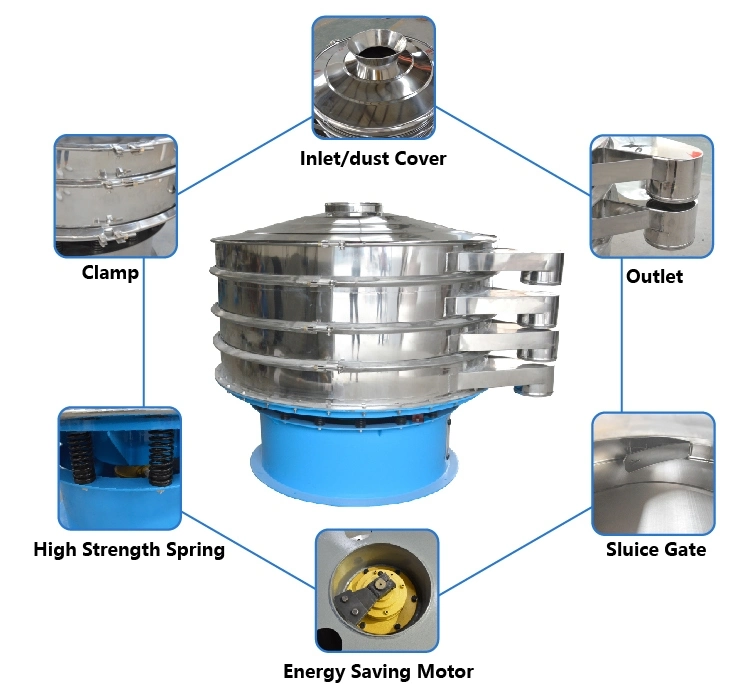

Particle Coffee Grading Sieving Circular Vibratory Separator ScreenProduct Description

We are engaged in manufacturing screening machine that is extensively used for separation of solids and gradation of material in accordance with their sizes. The vibrating screen is designed for screening the dry material through any mesh size as per particle size.

Manufactured also in double/triple/four decks for multiple grading sizes in the same batch in the same processProduct Advantage1. Easily change screen cloth as needed

2. Automatic discharge of oversized material

3. Can be applied for screening particle, powder, liquid in various industries

4. All- closed design, no dust pollution

5. Sort material into multi-levels at one operation

6. Low noise, less than 60 decibels

Product Parameters

| Model | Power | Effective screening diameter | Dimension(mm) | Layers |

| BZ400 | 0.18kw | 360mm | 580*580*560 | 1 |

| 580*580*670 | 2 | |||

| 580*580*780 | 3 | |||

| BZ600 | 0.25-0.55kw | 560mm | 800*800*750 | 1 |

| 800*800*890 | 2 | |||

| 800*800*1030 | 3 | |||

| BZ800 | 0.55-0.75kw | 760mm | 900*900*750 | 1 |

| 900*900*890 | 2 | |||

| 900*900*1030 | 3 | |||

| BZ1000 | 0.75-1.5kw | 930mm | 1160*1160*810 | 1 |

| 1160*1160*950 | 2 | |||

| 1160*1160*1090 | 3 | |||

| BZ1200 | 1.1-1.75kw | 1130mm | 1360*1360*885 | 1 |

| 1360*1360*1050 | 2 | |||

| 1360*1360*1275 | 3 | |||

| BZ1500 | 1.5-2.2kw | 1430mm | 1850*1850*990 | 1 |

| 1850*1850*1185 | 2 | |||

| 1850*1850*1380 | 3 | |||

| BZ1800 | 2.2-3.0kw | 1730mm | 2200*2200*1050 | 1 |

| 2200*2200*1250 | 2 | |||

| 2200*2200*1450 | 3 |

1. Once the machine on operation, vibration part shall not be connected or contact with any object.

2. When feeding materials, pay attention to ensure the uniform feeding.

3. When the material through down, keeping no big impact to damage the screen.

4. Before operation and power off, there should no be any material on screen surface.

5. If there is any abnormal sound in the operation, the machine should be shutdown immediately and to check.

6. Ensure vibration motor maintenance regularly.

1. Processed material

Name of processed material?Characteristic of processed material?such as water content, size of material, specific gravity2. MachineCapacity per hour you asked?How many layers you asked ?Sieve mesh for each layer?3. Working situationVoltage, Hertz, Phase4. Other special demandsContact us to learn more