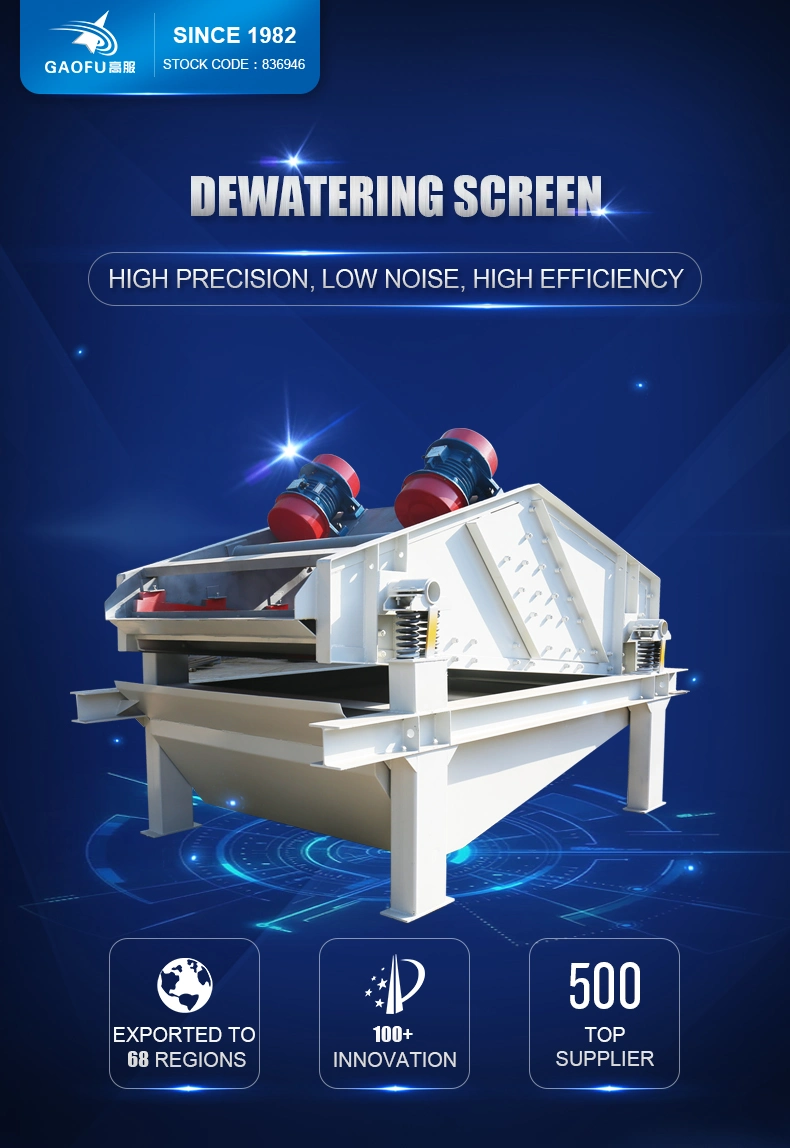

Sugar Industry Dry and Wet Grading Sieving Mechanical Dehydration Vibrating Screen Dewatering Machine

Basic Info

| Model NO. | VD-1845 |

| Type | Gfvd Series Dewartering Screen |

| Voltage | 220V/380V/or Other |

| Weight | as Per Model |

| Material | Carbon Steel |

| Material Feature | Other |

| Certification | ISO9001:2008, ISO9001:2000, CE |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| After-sales Service | Support |

| Advantage | High Efficiency Screening Equipment |

| Transport Package | Wooden Box |

| Specification | Vibrating Screen |

| Trademark | Gaofu |

| Origin | Henan, China |

| Production Capacity | 10000set/Year |

Product Description

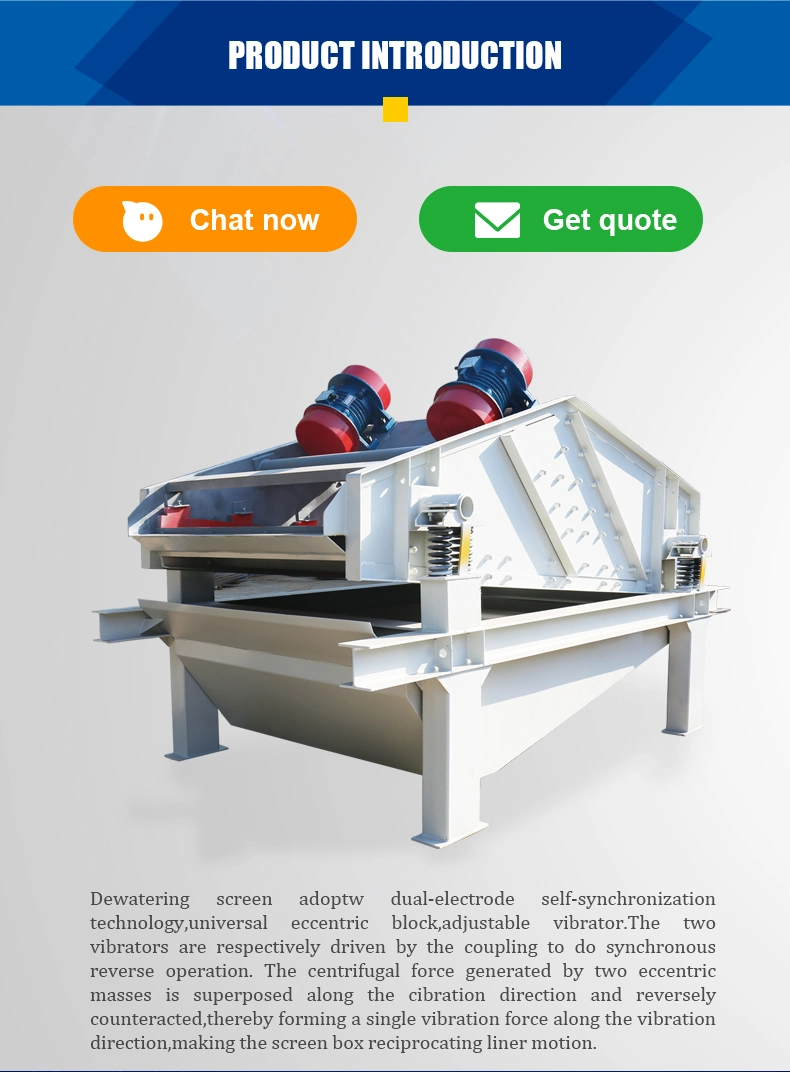

Relatively small size, large processing capacity per unit area, convenient for system process layout.

The high wear-resistant sieve plate has a long service life, modular assembly design, and easy replacement.

V-shaped sieve surface design, -5 ° sieve surface climbing dehydration, low water content and high efficiency of dry tailings discharge.

The specially designed frequency, amplitude, and low-consumption power source are suitable for 24-hour continuous dry discharge operations for various dehydration needs.

The riveting and welding combination of section steel components constitutes the main body of the frame with no internal stress, high strength, light weight and durability.

Scope of application

Dehydration, de-intermediation, and de-sliming of coal slime in the coal industry; fine-grained dry and wet screening, dehydration, and de-intermediation in the chemical industry; dehydration and de-intermediation of sludge in the environmental protection industry.

Applicable materials

Iron tailings, gold tailings, copper tailings, vanadium tailings, lead-zinc tailings, graphite tailings, quartz sand, zircon sand, glass sand, construction sand, foundry sand, building material sand, potassium feldspar Dehydration, solid-liquid separation of urban sewage, industrial sewage, river sludge, filtration of sewage treatment plants.

Product Parameters

Working Principle

The dehydration vibrating screen adopts double-electrode self-synchronization technology, general-purpose eccentric block, and adjustable amplitude vibrator. It is mainly composed of screen box, vibrator, support system and motor. The two unconnected vibrators are respectively driven by the belt coupling for synchronous reverse rotation. The centrifugal force generated by the two sets of eccentric masses is superimposed along the component force along the vibration direction, and the reverse centrifugal force is offset, thus forming a single excitation vibration along the vibration direction. , so that the screen box naturally reciprocates linear motion.

| Model | Material Granularity(mm) | Power(KW) | Motor model | Angle(°) | Amplitude(mm) | Exciter |

| VD-1036 | >0.15 | 1.8*2 | YZO 25-6 | 0~3 | 4~6 | None |

| VD-1236 | 2.2*2 | YZO 30-6 | ||||

| VD-1536 | 3.0*2 | YZO 40-6 | ||||

| VD-1836 | 3.7*2 | YZO 50-6 | ||||

| VD-1845 | >0.15 | 7.5*2 | YE2 160M-6 | 0~3 | 6~8 | ZQB 50-6 |

| VD-2138 | 7.5*2 | YE2 160M-6 | ZQB 50-6 | |||

| VD-2438 | 11*2 | YE2 160L-6 | ZQB 64-6 | |||

| VD-2445 | 11*2 | YE2 160L-6 | ZQB 64-6 |

Packaging & Shipping

Recommended Featured

Certifications

Company Profile

Xinxiang Gaofu Machinery specializes in manufacturing vibration screens and vibrating sieves. To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers. Thanks to production equipment, strong technical capabilities, improved detection means and strict managing system, we have enjoyed good reputation. our company has attained ISO9001:2000 certification and CE Certification. Our products sell well throughout China and are exported to North America, West Europe, Southeast Asia and other countries and regions. Do you want to improve your product quality? Do you want your products to become more competitive? Choosing Xinxiang Gaofu Machinery! We will be your friend in the way to success! And you will create a shiny future in 2017! Please visit our website: www.gaoful.com. Our tenet: "Honest Service, the Highest Quality".To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers.FAQ

1. who are we?

We are based in Henan, China, start from 2000,sell to Southeast Asia(40.00%),Domestic Market(27.00%),South America(10.00%),Eastern Europe(8.00%),Oceania(3.00%),North America(2.00%),Western Europe(2.00%),Africa(2.00%),South Asia(1.00%),Eastern Asia(1.00%),Southern Europe(1.00%),Central America(1.00%),Northern Europe(1.00%),Mid East(1.00%). There are total about 301-500 people in our office.2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Contact Us

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

Your email addressand telephone will not be shared or published!The proper selection of the vibrating screen depends on the material, mesh size,output required, method of input,abrasiveness of the material etc: 1. Screening product : _____2. Moisture:_____%3. Capacity:________kg/ hour4. Screen layer:_______5. Screen mesh size:______ mesh . ______ mesh. ______ mesh6. Voltage:______V,Frequency:______HZ, 3 phase7. SS304/316L stainless steel or Q235A carbon steel?